Aiming to be a cheerful and open company based on respect for people, a creative company full of vitality, a company that coexists with the community, and consequently a materially and spiritually rich company, we are contributing to a sustainable society.

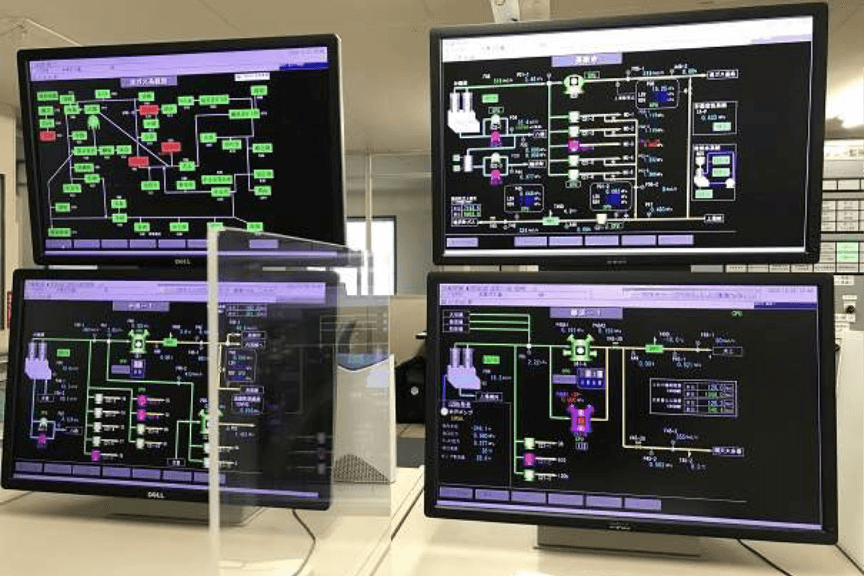

We monitor the operational status of all production facilities 24/7/365, and in the event of trouble, an emergency alarm system is activated to enable us to respond as quickly as possible.

The natural gas produced is used as city gas in the surrounding areas, so we have a responsibility to ensure the supply of gas is stable.

Our iodine production accounts for about 7% of the world’s total. Iodine is an element that is used in pharmaceuticals and disinfectants, and therefore requires a stable supply.

In 2020, we upgraded uninterruptible equipment and installed an emergency power generator to strengthen our backup system in the event of a power failure of the monitoring and alarm equipment. Going forward, we will further strengthen our Business Continuity Plan system.

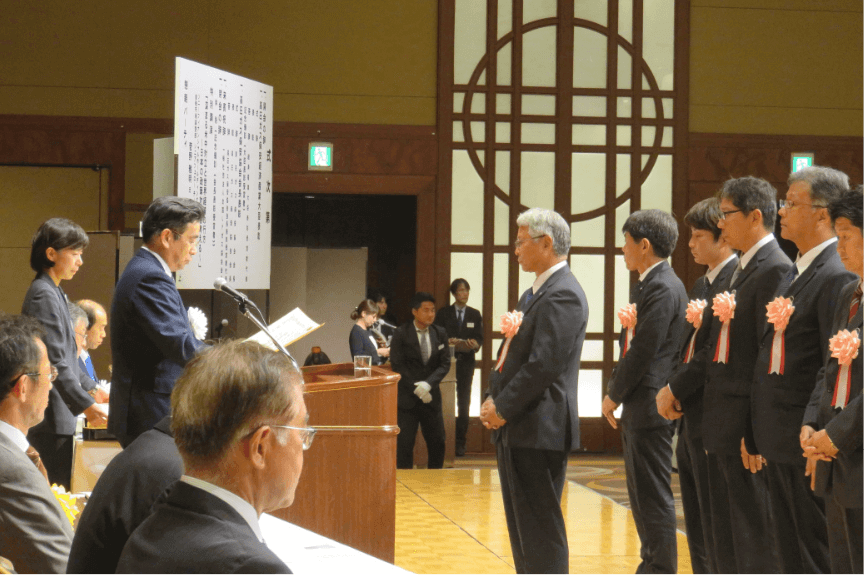

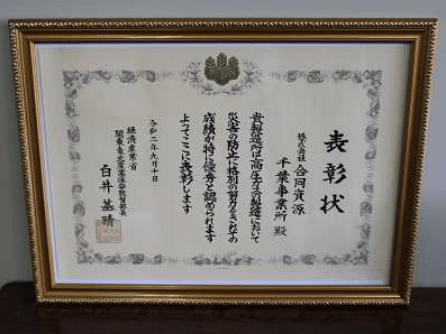

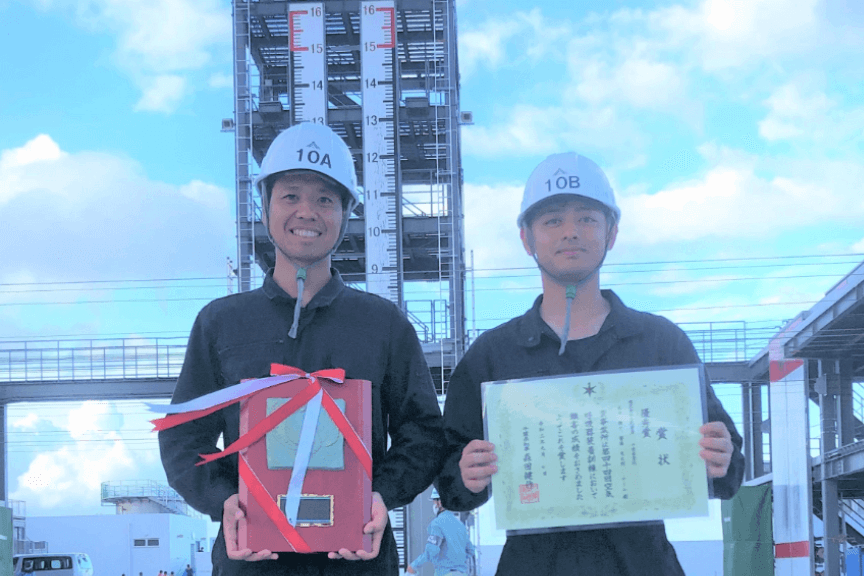

In addition, we received the Chairman’s Award of the High Pressure Gas Safety Institute of Japan in 2019, as a business site with particularly excellent safety measures (excellent manufacturing site) with regard to the structure and equipment at each facility and manufacturing methods used to produce high-pressure gas.

The Director’s Award of the Kanto Tohoku Industrial Safety and Inspection Department is given to outstanding business operators and persons who have made exceptional efforts and contributions to the prevention of disasters caused by high-pressure gas in the Kanto-Koshinetsu region of Tokyo and 10 other prefectures.

In 2021, we was awarded as an “excellent manufacturing site” for its efforts, contributions, and achievements in safety awareness as well as the prevention of disasters caused by high-pressure gas. In addition to continuous efforts to ensure the safety of high-pressure gas throughout the plant, the Basic Iodine Product Department was highly evaluated for its proactive efforts to improve safety technologies by upgrading the safety of facilities (measures against aging deterioration) and applying digital technologies (i.e., remote monitoring, web cameras, plant information management systems).

We will continue to improve and enhance our safety technologies and measures.

In order to ensure the safety of operations and facilities, each department conducts regular surveys to identify hazardous operations and locations, and assesses the severity, likelihood, and frequency of such risks. For those assessed as high-risk, improvements to reduce the risk are discussed within the department, and the results of taking measures are re-evaluated to help prevent accidents and troubles.

At us, each department conducts near-miss activities, verifies and assesses identified problems, and strives to prevent recurrence. We will continue to promote and improve environmental safety at each workplace.

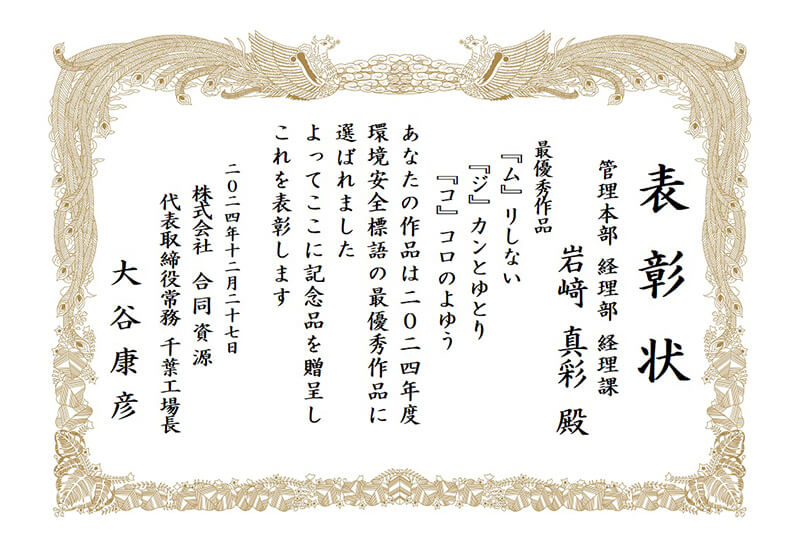

Each month, we invite entries for an environmental and safety slogan for each theme, and raise awareness of environmental and safety issues by displaying the best entries.

In 2024, a large number of slogans were collected again, and from among the excellent works for each month, the best work of the year was selected by a vote of all employees and presented with an award.

In addition, other excellent works are also submitted to the motto call for related organizations.

Hazards must be detected not only in the workplace, but also at home, when out and about, while driving, and in all other places in our daily lives. We do not simply forget about them because “nothing happened.” Instead, we strive to enhance safety by taking measures to anticipate hazards before they occur.

In addition to the hazard prevention activities conducted by each department, we also hold presentation meetings twice a year. Not only do we visualize activities and share information, but we also actively exchange opinions among other departments to feed back new ideas and opinions to our own departments.

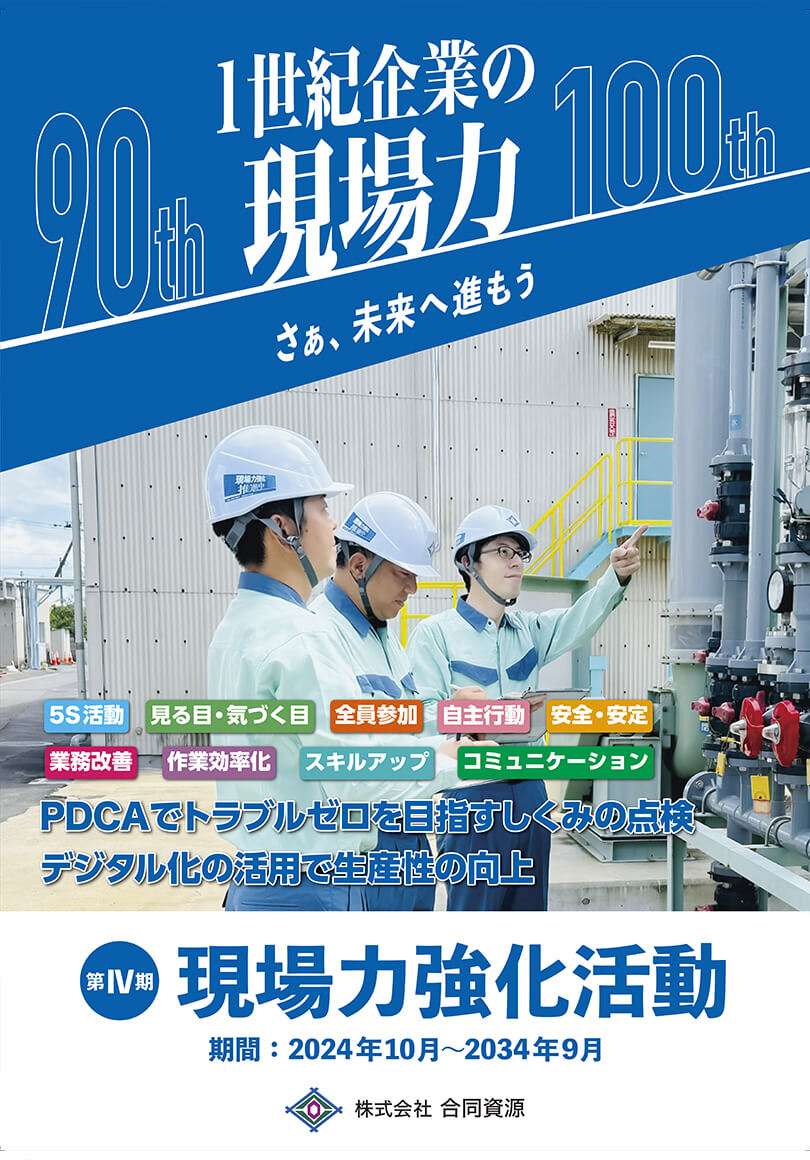

Our on-site power activities were declared active in 2015, and 10 years have passed with the participation of all employees.

Efforts in Phase I (FY2015-2017)

Thorough elimination of defects and losses

Review of safety, environment, quality, operation, facilities, and production technology management systems

Establishment of education system and implementation of education

Training of managers

Efforts in Phase II (FY2018-2020)

Thorough elimination of defects and losses and improvement activities

1) Identification of defects and losses in operations

2) Classify defects and losses into "quality," "safety," "equipment," and "environment/sanitation

3) Implement improvements for defects and losses

4) Sharing information (handing down technology, educational materials)

Phase III (FY2021 - FY2024) Initiatives

Promotion of multifaceted business improvement activities

Promotion of 3S and pursuit of 5S

Establishment of a workplace problem-solving system based on the PDCA cycle

The Phase III of the on-site capability enhancement activities has been completed, and in the final year, we have set the goal of “establishing a system to solve workplace issues by implementing the PDCA cycle.

The activities were carried out with the goal of "establishing a system for solving workplace issues by implementing the PDCA cycle.

During the factory manager's visit in May, the iodine production division reported on case studies of "efforts to stabilize quality" and "energy saving through optimization of operating equipment.

The iodine manufacturing division reported on case studies of "efforts to stabilize quality" and "energy conservation through optimization of operating equipment. The general comment was that the "establishment of a system to solve workplace issues by repeating the PDCA cycle" requires further inspection, and it was decided to continue this activity.

The committee decided to continue this activity.

Based on the above review, we have started the IV phase of activities from FY2025.

Since there was an industrial accident involving tripping and falling that resulted in a broken bone, we removed unnecessary foundations from the site.

During the National Safety Week and the National Occupational Health Week, the chairperson and vice chairperson of the Safety and Health Committee conduct workplace patrols.

We will ensure safety in workplaces by carrying out the PDCA cycle, raising issues through patrols, making improvements, and horizontally deploying the PDCA cycle.

The Environment and Safety Office regularly inspects the Chiba Plant and other in-house work sites at each location to check safety measures, provide guidance, and call for 5S.

During patrols, we make continuous improvements through the PDCA cycle together with the relevant departments in order to identify potential hazards in construction and operations and prevent occupational accidents and injuries.

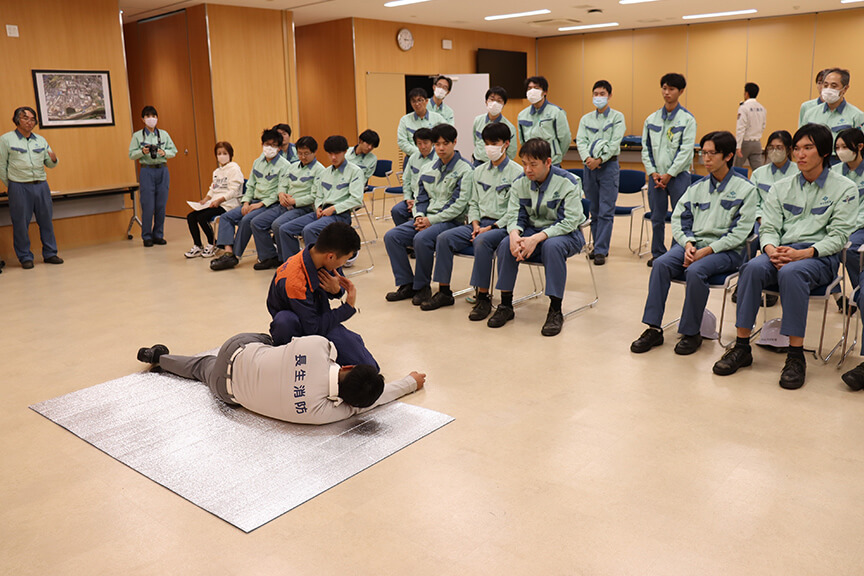

We regularly provide air respirator fitting training and AED resuscitation training to all employees.

In addition, with the guidance of members of the Chousei Branch of the Chousei County Fire Department, we conduct annual drills on the use of water extinguishers and outdoor fire hydrants, as well as comprehensive evacuation guidance drills.

We regularly conduct accident simulation training at each workplace to identify new risks and help prevent human error.

For high-risk cases or cases where damage is expected to be extensive, we conduct drills to set up a crisis response headquarters at the same time.

In 2023, we conducted crisis headquarters establishment drills for three of the assumed accident drills: brine and gas leakage at a plant in Chosei-gun, chlorine gas leakage from a flange section, and a fire accident caused by static electricity.

To ensure appropriate disaster prevention activities in the event of an emergency, we provide air respirator fitting training to all employees four times a year. By setting a goal for the fitting time, we aim to train our employees to put on air respirators quickly and properly.

In the 44th annual air respirator fitting training held at the Chiba Fire Academy in September 2020, our company won second place among 20 companies in the prefecture that participated, and received an award for excellence.

Based on our experience with the typhoons and torrential rains that occurred in 2019, we recognized the need to quickly ascertain the safety of our employees and their availability to work, and introduced a safety confirmation system as part of our business continuity plan (BCP).

The responses to the simultaneous calls are automatically counted, so the situation can be quickly ascertained, and the system can be used as a tool for collecting and communicating information to enable the initial response to business recovery activities.

Safety confirmation drills are held once a year to familiarize employees with the system and raise their awareness of crisis management.

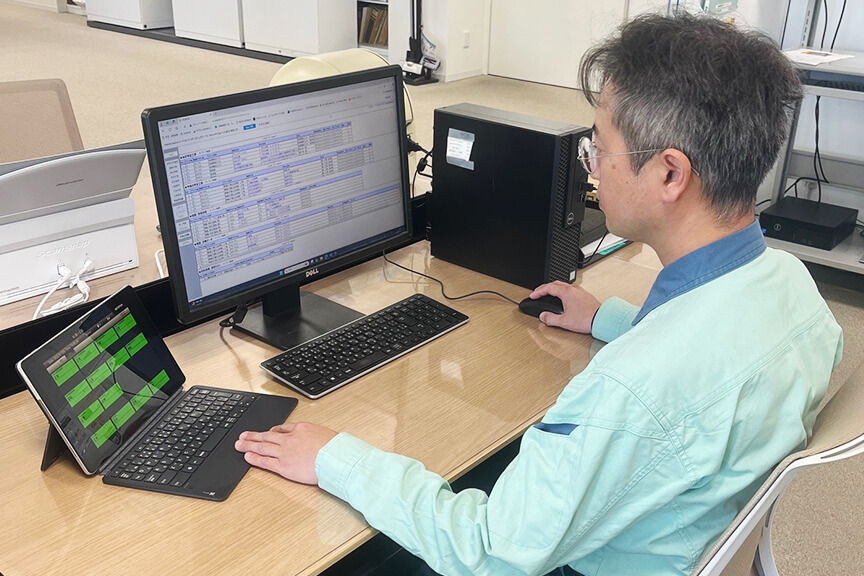

We have introduced an equipment maintenance management system to manage maintenance cycles, plans, histories, and problems for each piece of equipment. As a result of the tabulation and analysis of these data, the majority of trouble causes that occurred frequently in 2023 were caused by piping.

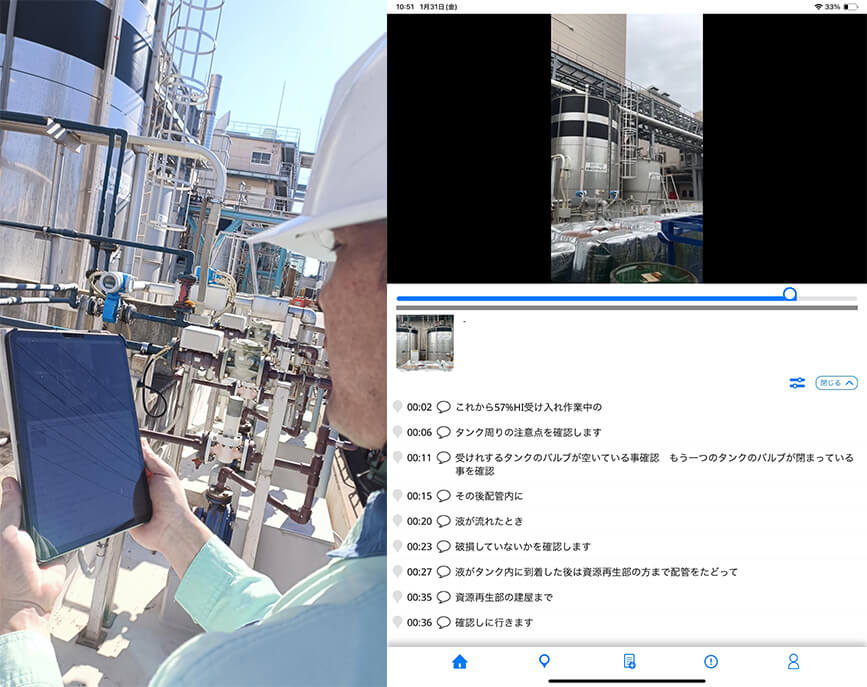

In addition, we have introduced tablet devices for daily inspections and have attempted to import inspection records directly into the system, thus improving work efficiency compared to the conventional method.

In order to promote manufacturing DX, it is fundamental to establish a Wi-Fi environment in the factory. We repeatedly survey the signal conditions within each factory to determine the optimal installation points.

This maintenance has led to the use of remote cameras and video manuals by the manufacturing process. we are proceeding with the safety and stability of Wi-Fi, which is the infrastructure for DX activities.

In September 2023, we introduced and began utilizing software to create video manuals. The software visualizes skills and creates video manuals of work processes, techniques, and business processes through tablet terminals.

Skills that cannot be read in writing can be visualized, and the skills of skilled workers can be efficiently passed on to the younger generation, while reducing the labor required to create manuals.

Drones are utilized to gain an overall picture of company-owned land and piping roads that are not easily accessible by humans.

Drones are also used to diagnose the deterioration of the outer wall above the blowout tower and for maintenance management of the damaged condition of the top of the piping racks.

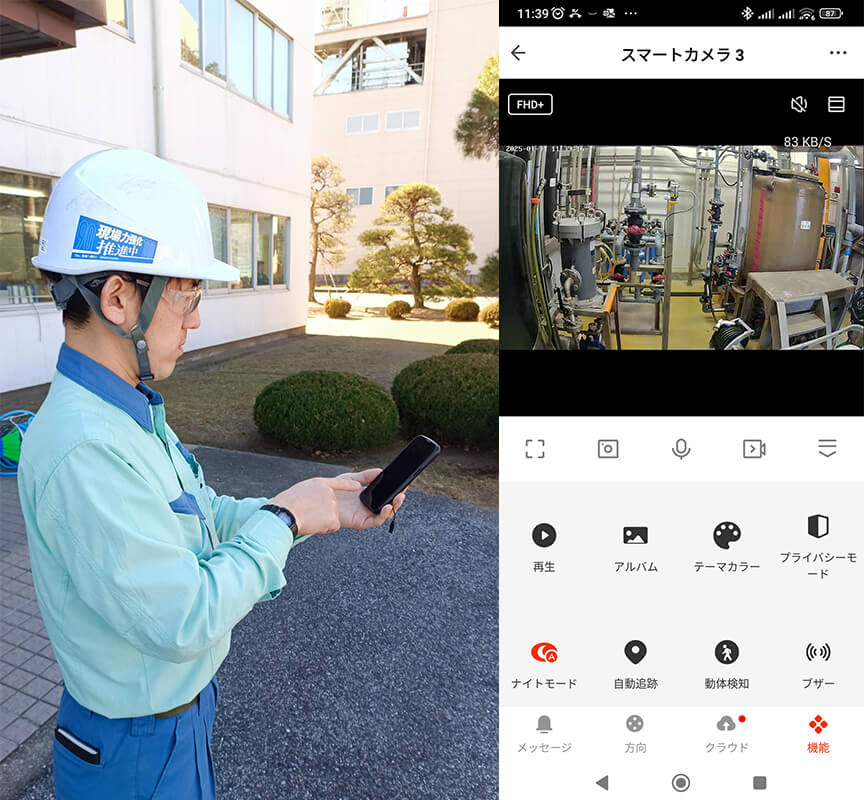

By utilizing a wireless communication system, the status of facilities can be monitored in real time from a distance with a tablet terminal, enabling appropriate initial response in the event of a facility malfunction.

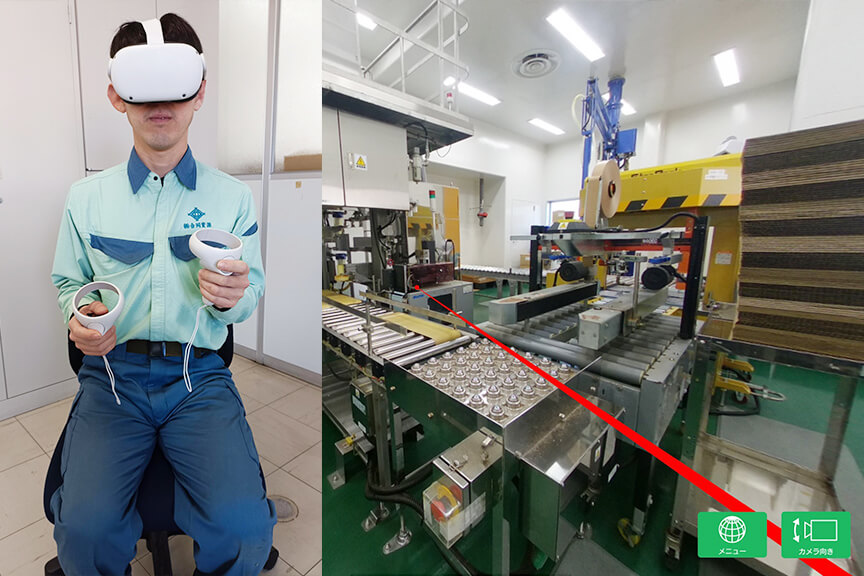

By taking 360-degree photos of the factory and reproducing them using dedicated software and a VR headset, the factory can be recreated without visiting the site. Hazard risks and examples of past problems can also be displayed in the same space, making it a useful tool for safety and health education.

In the event of an abnormality at a facility that is in continuous operation during the night, a web camera can be used from a distance to monitor the condition of the facility in real time, allowing for appropriate initial response.