Natural gas is a clean energy source that is friendly to the earth and people, and can reduce environmental impacts such as global warming and air pollution. Natural gas is one of the few energy sources produced in Japan, and we have a great social responsibility to be part of supplying it. We will keep making utmost efforts to ensure a safe and stable supply of natural gas.

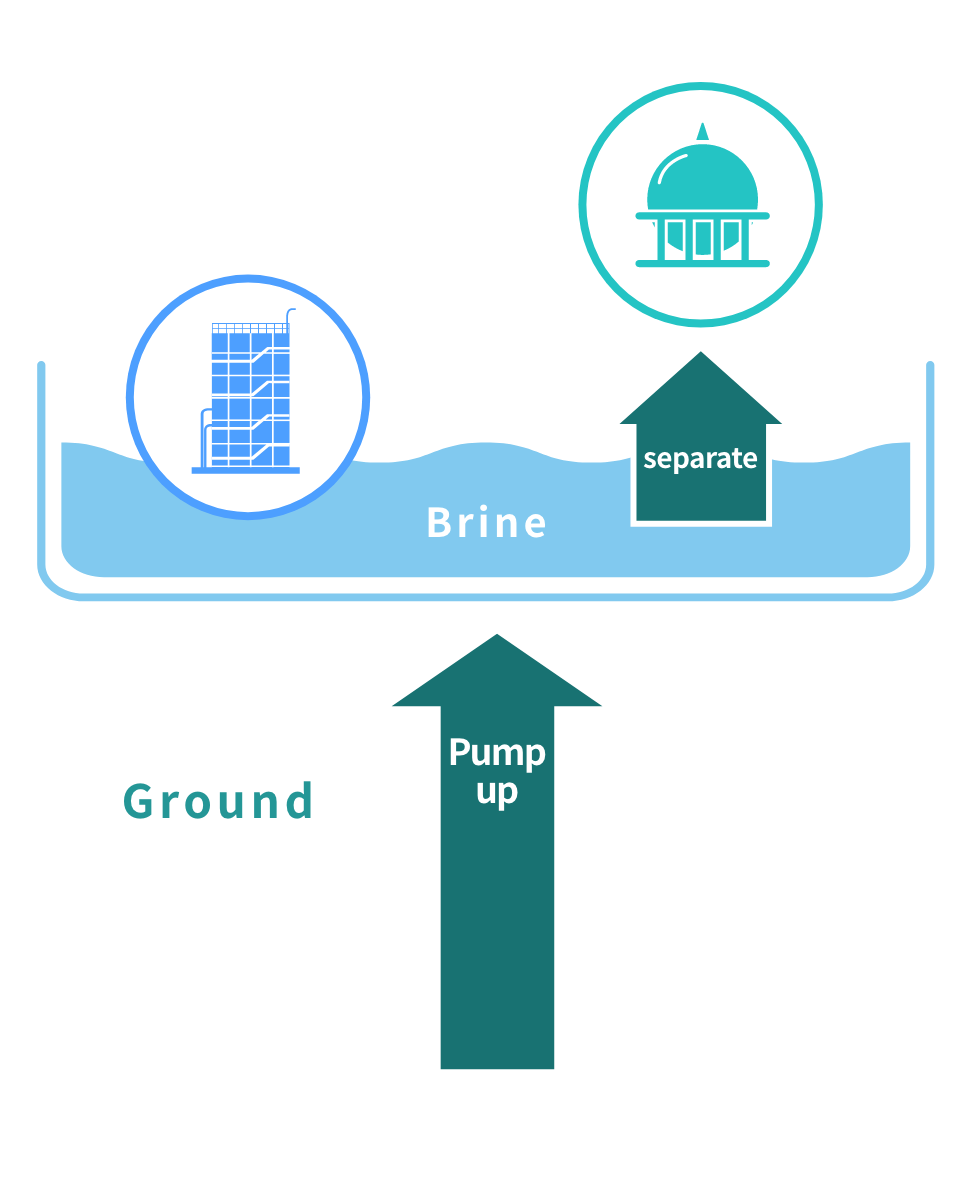

Natural gas and brine are pumped up from underground, and separated by a separator above ground, and then the natural gas is supplied as fuel to households through gas holders and pipelines by using compressors.

You can pinch out to enlarge the photo.

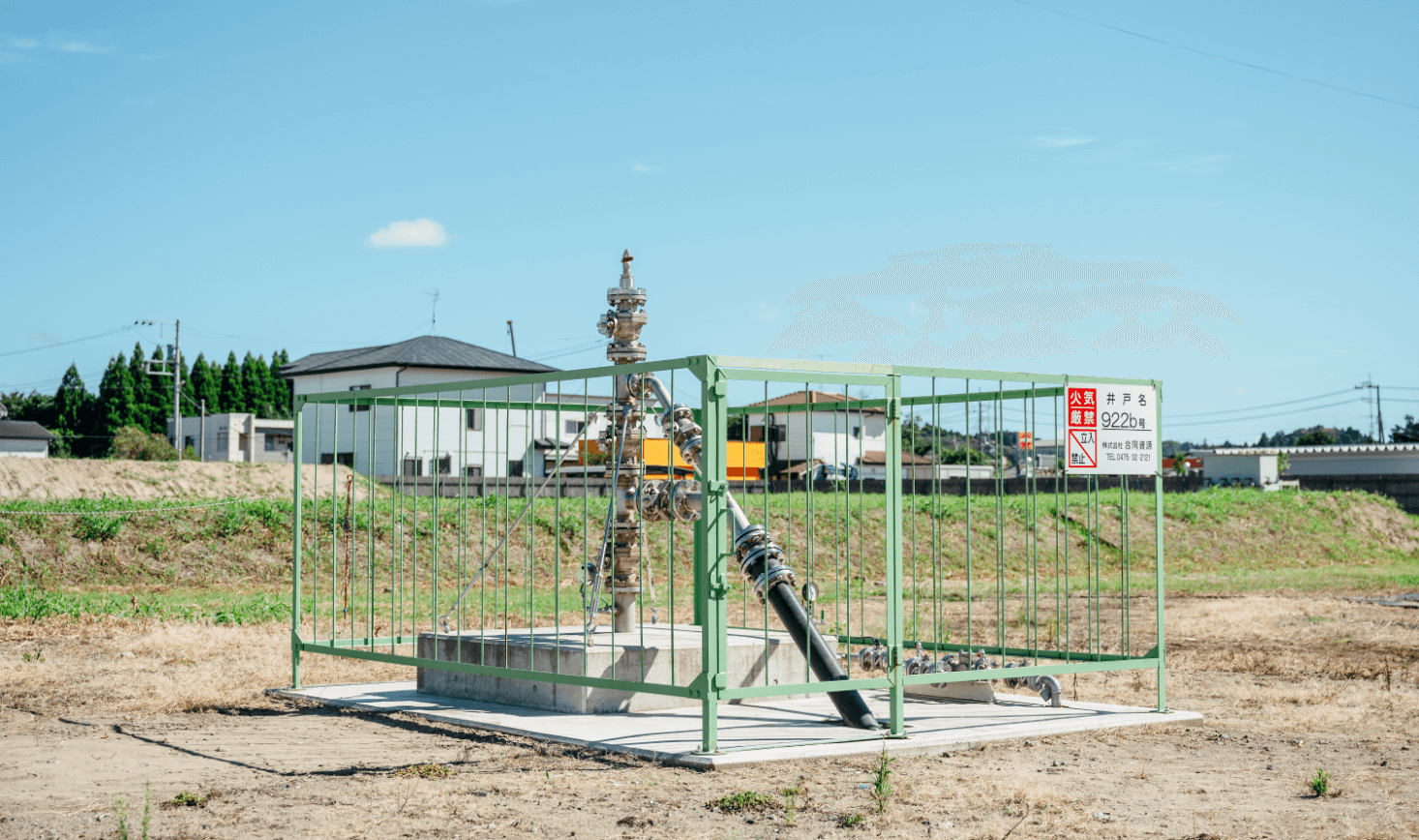

Well

Separator

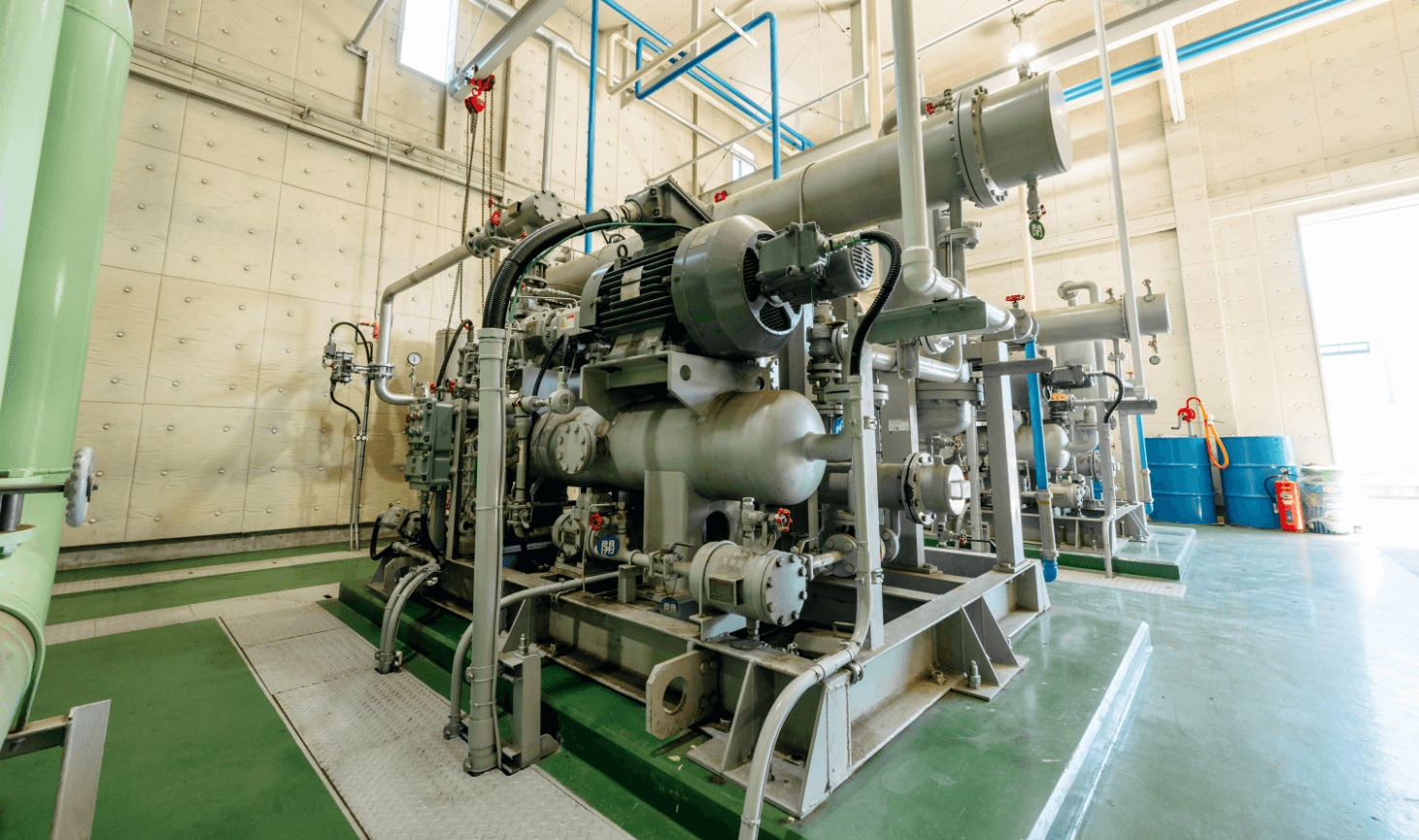

Gas feed compressor

The well is reinforced as necessary, perforated tubes with many holes are inserted into the gas layer, and well-head equipment is installed on the surface. From here, underground water-soluble natural gas is pumped out.

The natural gas and brine pumped up to the surface are separated.

Natural gas is supplied to customers through gas transmission pipelines.

Natural gas dissolved in brine due to pressure deep underground turns into a gas and is separated from brine when pumped up to the surface. The separator separates the gas and liquid into separate channels, and then the natural gas is supplied to households and factories to be consumed as fuel. On the other hand, brine containing iodine is recovered in liquid form to an iodine plant where it is turned into various iodine products.

The operation phases covering from production to supply of gas are bulk-controlled by the telemetering system. Since the gas supply operations are totally controlled with computers, safe and stable supply is ensured.

There are more than 50 plants that integrate various compressors, pumps, and control equipment. Each plant is connected to the central monitoring room at the Chiba Works by a telemeter system to ensure a stable supply through constant remote monitoring.

We are working together with local communities to make use of the plants for cogeneration.